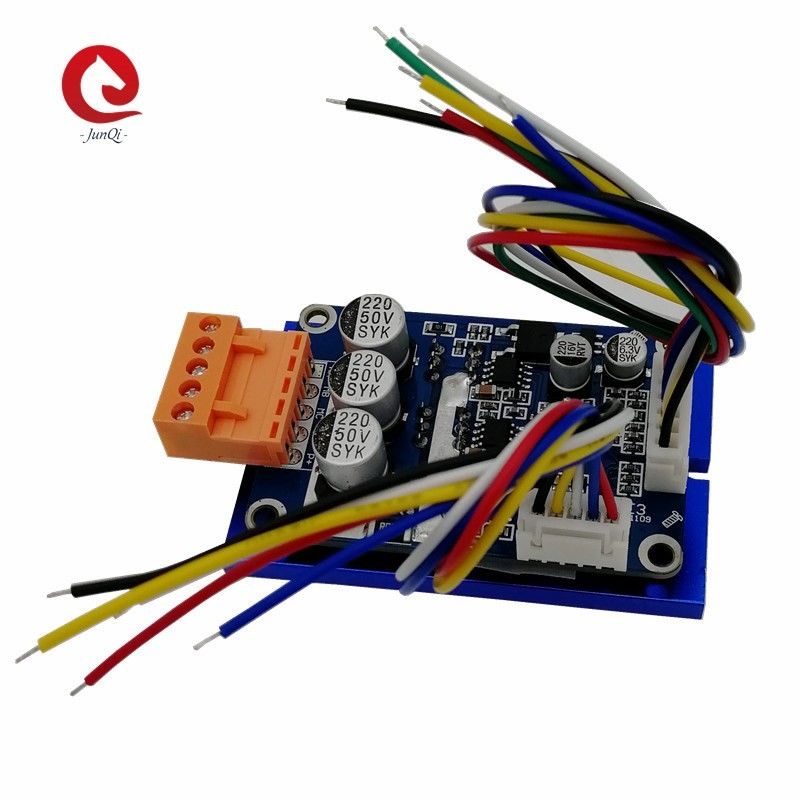

12V,24V,36V,5A,10A,15A 500W brushless DC motor driver,Hall sensor,brushless DC motor speed controller JYQD-V7.3E3

JYQD-V7.3E3 12V-36V brushless DC motor driver circuit board

| MODEL |

OPERATING TEMPERATURE(℃) |

OPERATING VOLTAGE(V) |

MAX CURRENT (A) |

· CONTINUOUS OPERATING CURRENT

(A)

|

PWM SPEED REGULATION

(1-20KHZ)

|

ANALOG VOLTAGE SPEED REGULATION (V) |

Speed pulse signal output |

| JYQD-V7.3E3 |

-20—85℃ |

12V-36V |

16A |

15A |

Duty cycle

0-100%

|

0-5V |

√ |

ATTENTION:

1: This brushless DC motor driver board is widely apply to DC Brushless with Hall sensor (120°angle) three-wire motors

2: please make sure to add heat sink when the output power more than 60W.

When installing the heat sink, please add insulation layer for 6pcs MOS. It will damage the driver board permanently without insulation,and also apply Heat-Conducting Silicone Grease on the insulation for better cooling.

3: As the BLDC motor factory may use different Hall sequence,if the motor start abnormal, can't start or the current getting to high, please adjust the sequence of the Hall, or the driver will be damaged.

4: Please offer the right voltage to the driver, do not exceed the operating range. and the driver has built-in 5V for speed control, DO NOT connect extra power supply( 5V ) into the driver for speed controlling, it will damage the driver.

Specifications

| Operating Voltage |

DC 12V-36V |

| Operating current |

≤15A |

| Output power |

≤500W |

| Speed control |

0.1V-5V or PWM input |

| Operating temperature |

-40-85℃ |

| Operating humidity |

≤90% |

| Protection |

Overload protection, locked-rotor protection, over-current protection |

| Functions |

Speed pulse signal output, soft reversing (485,CAN port optional) |

| Overall dimension |

63X42.5X17mm (L*W*H) |

| Net weight |

55 g |

| Optional component |

Speed regulating potentiometer

external 5 digit tachometer

|

Wiring instructions

1. Control port

5V —Driver board internal output voltage, external potentiometer or switch for speed adjustment and reversing operation

Z/F —Rotating direction control ports. Connect “5V” high level or no connect is Forward direction, connect 0 V low level or connect to GND is reverse direction.

VR —Speed control port. Analog voltage linear speed regulation 0.1v -5V, The input resistance is 20K Ohm ,connect with GND when input PWM speed regulation, PWM frequency:1-20KHZ; Duty cycle 0-100%

EL —Enable port control. Connect 5V or no connect to allow operation, connect GND to forbid operation.

Signal— Speed pulse signal output

GND—Used for Driver board internal control

2. Power port

MA ----motor phase A

MB ---- motor phase B

MC---- motor phase C

P- ----DC-

P+----DC +

3:Hall sensor port

Ha--- Hall a

Hb---Hall b

Hc---Hall c

GND---GND

5V---5V output

4. Use shielded wires if the drivers board has more than 50 cm distance from the motor, otherwise it may lead to abnormal driving, affecting the normal use.

5. Control port distance:2.54mm. Power port distance:3.96mm

6.Pay Attention to the insulation between the driver MOSFET and the heatsink or the installation plate.

Mounting dimension

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!